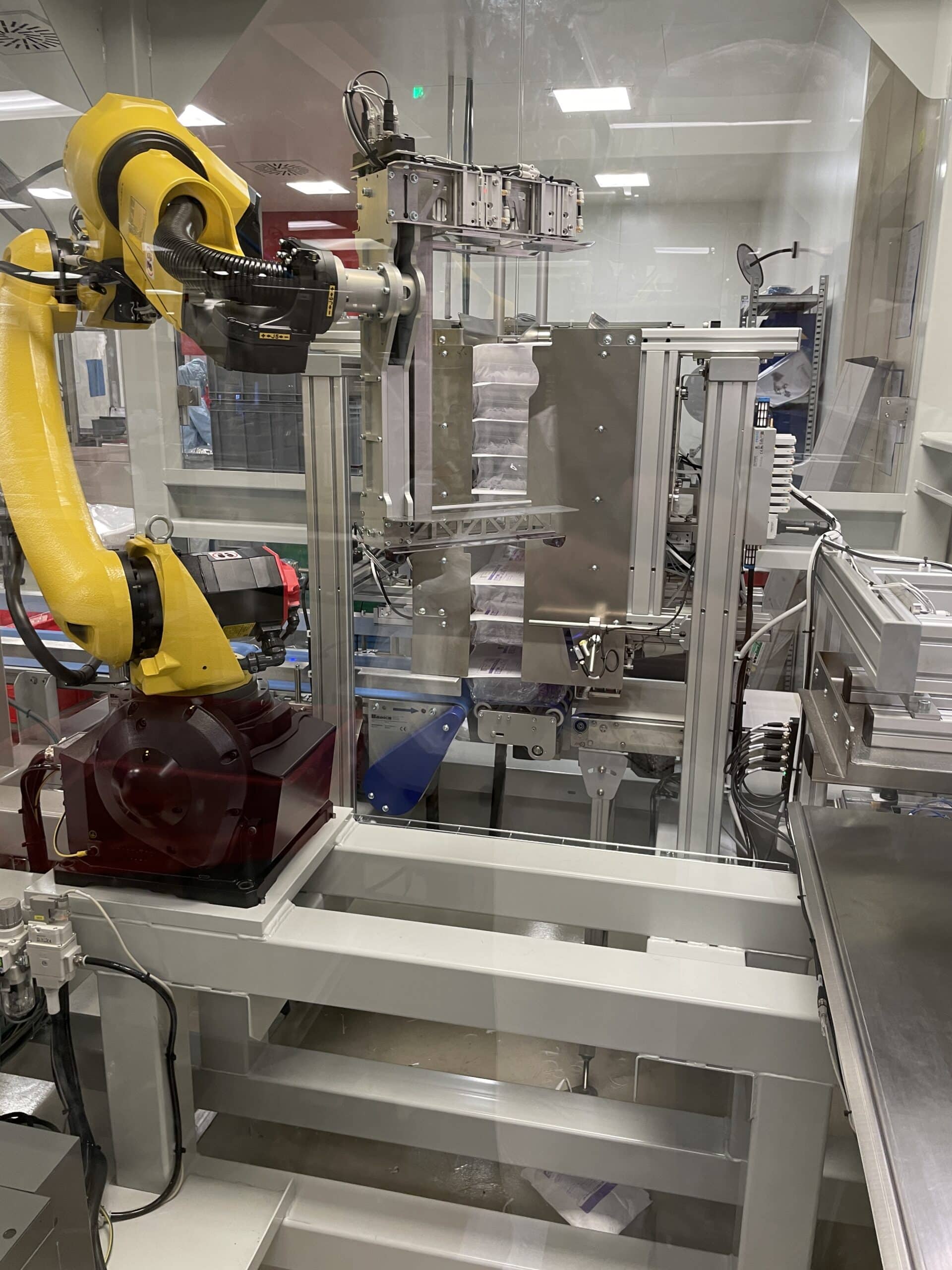

Custom solutions for specific requirements

At Ronetic, we believe in 100% custom-made solutions. Our products can be adapted to your specific needs. Whether you are looking for a stand-alone machine or integration into the existing production line, we offer flexible solutions that perfectly suit all your needs and requirements.

Experience and collaboration for optimal results

With more than 20 years of experience in robotisation, mechanics and control engineering (mechatronics), at Ronetic, we have the expertise to take on complex challenges. Our dedicated team of experts works closely with you, involving you in the design phase. This collaboration enables us to create custom solutions to meet specific requirements and expectations.