Reliable customised solutions and service

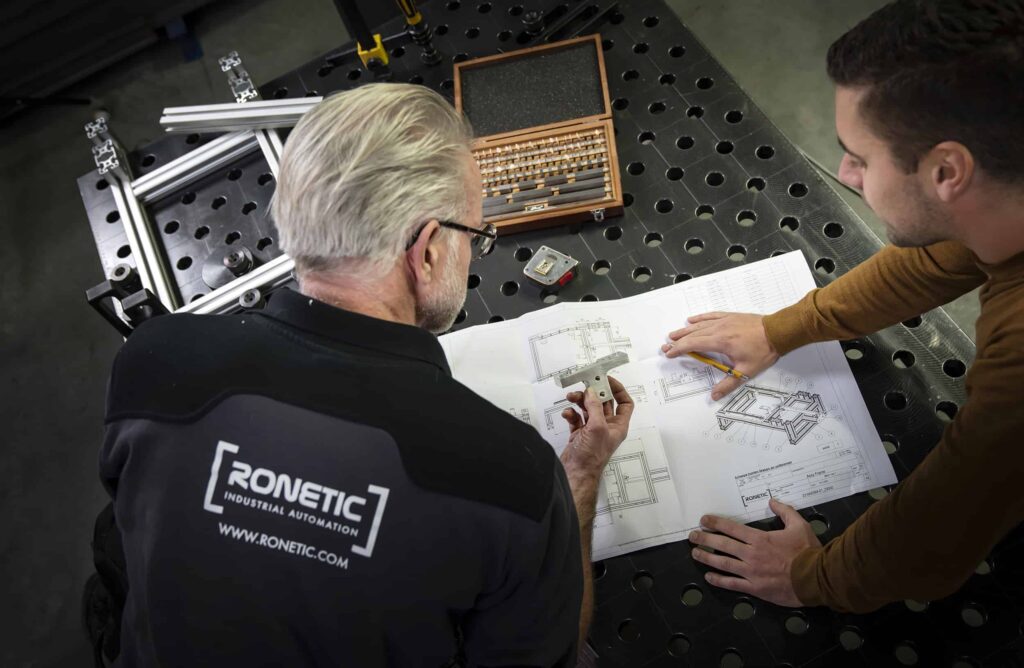

At Ronetic, we believe in 100% custom-made solutions that fit your business needs perfectly. Our experienced team of specialists works closely with you to design and implement an injection moulding solution that meets all the specific requirements. We offer various types of control systems depending on the requirements. We also have our own skilled professionals who provide custom parts and we are abe to offer competitive rates for standard manufactured parts through our partners.

Our involvement in the design phase and years of experience in robotisation and control engineering enable us to deliver reliable machines with fast and efficient installation at yoursite. We are alwayson hand to provide service and maintenance to keep injection moulding production lines running smoothly.

As an authorised partner of leading brands such as ABB, FANUC and DENSO, we can draw on an extensive stock of high-quality injection moulding machines and robotics components. This enables us to offer the best solutions that meet the specific requirements of your injection moulding business.